Run a well-oiled value chain by automating end-to-end processes with NetSuite manufacturing ERP

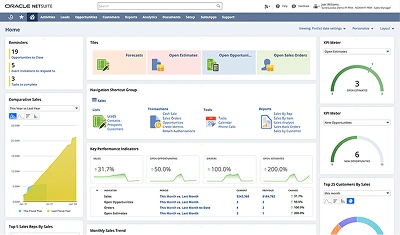

NetSuite manufacturing ERP Unifies inventory, production, and financial data in one system to eliminate silos and improve coordination. It will track stock levels, movements, and demand accurately to prevent overstocking or shortages. Moreover, with NetSuite manufacturing ERP in place, you will be able to reduce manual planning errors and keep production on time with dynamic scheduling tools. It also offers real-time tracking and customizable reporting capabilities to simplify audit and regulatory compliance.

Many manufacturers struggle with visibility across their supply chain, leading to delays and increased costs.

Using disparate systems can create data silos and complicate workflows, making it difficult to achieve cohesive operations.

Poor product quality can lead to costly recalls and damage your brand reputation.

Your existing systems may struggle under increased demand or when expanding into new markets.

NetSuite ERP for manufacturing offers comprehensive modules to optimize and enhance manufacturing operations. It provides advanced capabilities for managing complex manufacturing environments, including work-in-progress tracking and detailed production planning.

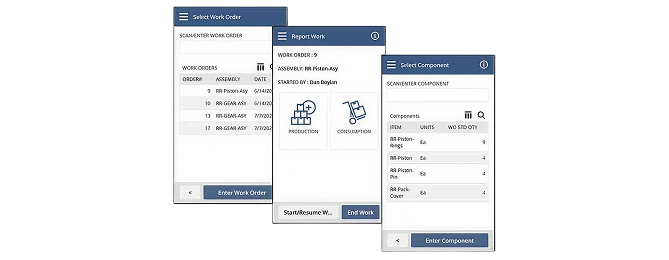

Modernize shop floor operations for production team with mobile scanners for NetSuite Manufacturing Mobile SuiteApp. This solution comes automatically with your NetSuite Manufacturing purchase. The system supports independent processes for component consumption, finished good production, and financial updates.

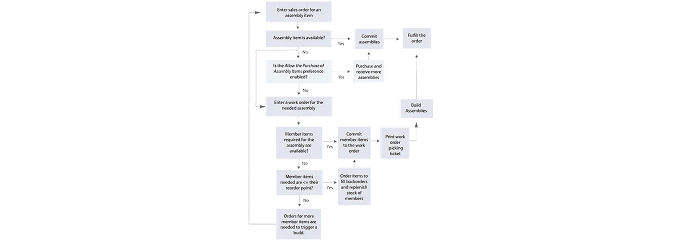

Managing resources, monitoring expenses, and optimizing production workflows are some of the complex elements frequently involved in manufacturing processes. NetSuite’s Work Orders & Assemblies module streamlines these difficulties and is ideal for companies trying to increase manufacturing efficiency.

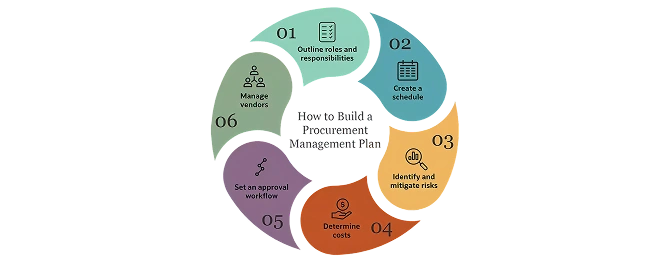

Utilize NetSuite’s robust features to optimize procurement for manufacturing. Simplify purchasing, procure-to-pay, and supplier management procedures with real-time visibility. Receive the right materials at the right time and location with requests for bids, blanket purchase orders, and purchase contracts.

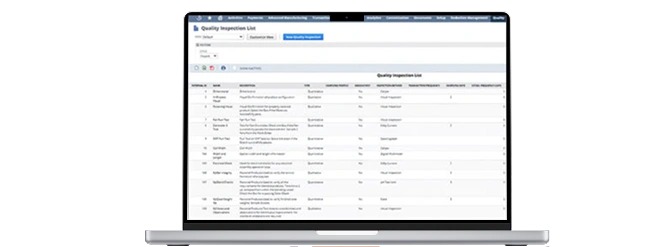

NetSuite Quality Management assists producers in maintaining superior product quality while cutting expenses. To preserve quality throughout your supply chain and manufacturing operations, you can establish pass/fail criteria, specify inspection plans, track outcomes, and simplify in-process inspections.

This module helps forecast demand accurately, ensures production aligns with market needs, and minimizes excess inventory. With demand planning, you can predict required inventory based on historical demand or sales forecasts.

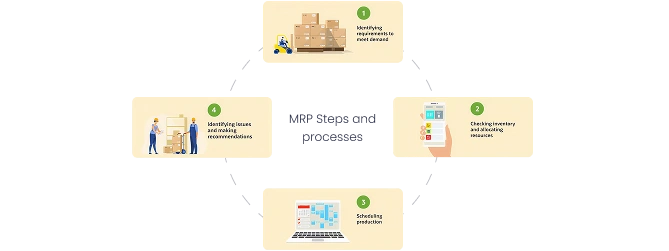

By precisely predicting demand and making sure the appropriate resources are accessible when needed, you can minimize excess inventory and production delays while optimizing inventory and production operations. MRP also streamlines procurement, improves resource planning, and increases overall production efficiency.

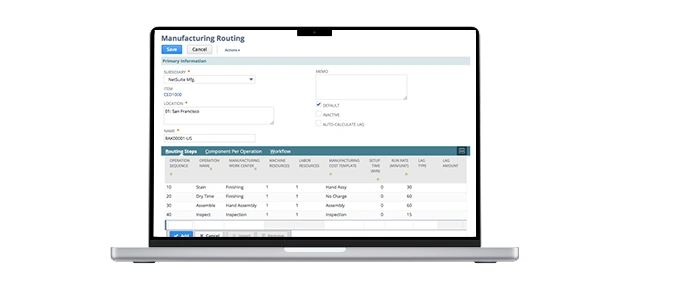

WIP and routing make it possible to specify the manufacturing process’s routing, the resources required to finish it, and the anticipated time and expense needed. Additionally, scheduling engines can assist in identifying resources that are over or underutilized based on routings.

If you are implementing NetSuite for your manufacturing business, you must be looking for precision in the core manufacturing operations. These features can help you achieve tangible results with a competitive edge:

You can plan, schedule, and oversee production, work orders, and shop floor activities to meet deadlines and minimize downtime and waste.

It helps you optimize inventory levels, track raw materials, reorder, and manage stock in multiple locations to meet production demands.

You can integrate relevant modules with NetSuite and manage procurement, logistics, suppliers, and demand planning for better coordination and reduced lead times.

With accurate financial management, you can maintain business profitability. You’ll get budgeting and forecasting, cost management, and other cost-control features.

You can monitor and control all shop floor activities in real-time. It is best for tracking work orders, machine performance, labor management, production, and quality control.

Our solution enables you to conveniently estimate the cost of a product, whether it involves assembling or manufacturing or procurement from multiple vendors. By leveraging our engine, you can instantly calculate the product cost at runtime, eliminating the need to create an item in NetSuite. This not only provides you with the speed you require for quoting and costing items but also ensures accuracy in the process. This feature integrates well with netsuite advanced manufacturing capabilities.

With our innovative integration of Zebra's Browser Print Utility, we've simplified label printing for your business. Our solution automates the entire process, allowing you to effortlessly send labels directly to your Zebra printer with a single click.

License Plating helps track and manage inventory, particularly at the pallet, bin, or container level. This custom solution will help you identify and track specific items or groups of items, facilitating inventory movements and transactions.

This allows processing of work orders based on batches and custom filters. The screen should enable users to issue, complete, and close selected work orders and perform the operation completion step within a single interface.

By integrating the Manufacturing Production Completion and Labeling Solution with NetSuite, this solution facilitates efficient data entry, ensures precise inventory tracking, and automates label generation, thereby improving operational efficiency and reducing manual errors.

Connect your NetSuite with any platform of your choice and increase customer retention with an integrated CRM for managing contracts, subscriptions, and renewals. For communication, use mailing system integrations to streamline and manage interactions effectively.

In our NetSuite ERP implementation methodology, we consider the best practices from our deployment experiences and NetSuite’s recommended Methodology.

You need to evaluate what your manufacturing operation truly needs thoroughly. What specific challenges are you facing on your production floor? Where are the bottlenecks in your supply chain? By setting clear, measurable goals together, we can customize the ERP for your business. With defined objectives, we can make a roadmap to guide our implementation process and ensure you get the outcomes you expect.

Your team's buy-in is essential for a successful implementation. With your key stakeholders involved from day one, we can prevent issues before they arise. We've seen implementations struggle when key people weren't consulted early enough. By bringing everyone to the table early, we face less resistance during rollout, and your team can adopt the system more readily.

Every manufacturing business operates differently, and the ERP implementation should reflect that. We can customize NetSuite to match how you operate. You might need specialized workflows for your quality control process or custom reports that track your specific KPIs. With a configured system, there will be less disruption. Our goal is to have NetSuite work for you, not make you work for NetSuite.

We make sure that our NetSuite implementation communicates with your existing technologies. Whether you need to maintain your specialized equipment monitoring software or integrate with your third-party logistics provider, we'll integrate NetSuite with them. We can proudly promise you a smooth data flow between systems with minimum disruption. This is especially critical for businesses relying on advanced manufacturing NetSuite to unify shop floor operations with enterprise data.

We provide training to teams who are new to NetSuite and have different roles in your manufacturing operations. Other than training, we offer ongoing support and 24/7 support even after go-live. We guide you throughout the implementation process so you can get the best out of NetSuite for years to come.

Helped sort the data out into a meaningful format and migrate a huge data set to the ERP.

Helped reduce operating costs, minimize follow-up time for financial reporting, and manage supply chain.

Hear directly from our clients who have transformed their manufacturing operations with our NetSuite implementation expertise.

We have been on Sage for more than 20 years, so we knew moving to a completely new system would be challenging. Due to the immense efforts of the Folio3 team, it was a lot smoother than we had hoped.

We at Biomason are truly grateful for Folio3’s expertise, patience, & diligence in making our implementation of NetSuite a success. We really appreciate all the information sharing & responsiveness to our requirements.

Our consultants understand the ins and outs of discrete manufacturing processes.

Offer NetSuite customization according to your business workflows

We ensure quick deployments without compromising performance.

Our team stays with you every step of the way, even after ERP implementation.

Manufacturers choose NetSuite for its cloud-based flexibility, real-time data access, industry-specific features, and ability to manage end-to-end operations from one platform.

Yes, NetSuite for Manufacturing is scalable and supports small manufacturers by automating key processes such as inventory management, production scheduling, order processing, supply chain management, financial tracking, and demand forecasting. This helps them gain control and scale efficiently.

Manufacturers without an ERP system face poor inventory control, data silos, production delays, and limited visibility across operations, which can lead to higher costs and reduced efficiency.

As a trusted NetSuite implementation agency, Folio3 specializes in providing comprehensive NetSuite manufacturing software implementation services. Our NetSuite manufacturing expertise and industry experience allow us to deliver tailored solutions that optimize your manufacturing processes. Our team offers full-scale NetSuite manufacturing consulting to ensure you get the most from your ERP investment. For manufacturers scaling fast, advanced manufacturing netsuite options from Folio3 ensure you’re equipped with a flexible and future-ready platform.

NetSuite’s pricing is typically based on a subscription model that includes the number of users, modules, and features required, meaning pricing can vary based on the specific needs of your business.

NetSuite does not offer a free trial, but potential customers can request a demo or consultation to understand the product’s capabilities and pricing structure. You can also reach out to Folio3 for a demo.

NetSuite Manufacturing ERP pricing varies based on the number of users, features, and customization options your business needs. It’s a subscription-based model, with a monthly fee depending on your specific requirements.

No, NetSuite provides transparent pricing. However, additional costs may arise for customizations, integrations, or advanced features that are not included in the standard plan. There is a license fee and then an implementation cost. You can reach out to netsuite.folio3.com for pricing.

Yes, NetSuite for manufacturing is scalable and can be tailored to fit the budget of small manufacturers. The pricing structure allows for flexibility. It enables businesses to pay for only what they need and scale as they grow.

Folio3 can customize NetSuite manufacturing software to fit your specific manufacturing processes. We understand that manufacturing operations can vary significantly across businesses. Our team will collaborate closely with you to configure NetSuite ERP, tailoring workflows, data fields, reports, and dashboards to align with your unique manufacturing requirements.

© 2025, Folio3 Software Inc. All rights reserved.