Stay on top of every stage, from cutting and stitching to embroidery and finishing. Whether your production is in-house or outsourced, NStitch as a fashion ERP enables you to monitor and manage production progress.

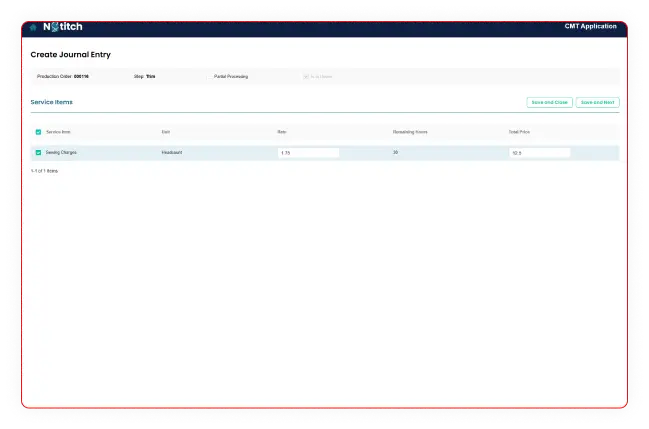

Maximize productivity by timely capture of financial transactions and getting real-time reports on financial performance.

Manage stock better and avoid stockouts by gaining complete visibility across all channels.

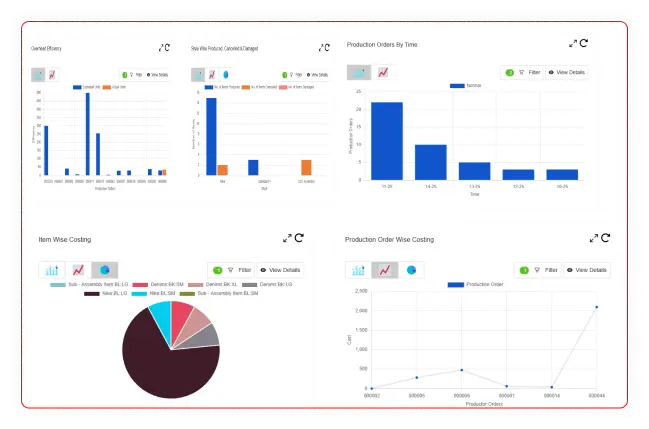

Maximize efficiency in operations and gain a clear view of your bottom line across channels.

Improve order-to-cash cycle and minimize holding costs by combining key sales and fulfillment functions.

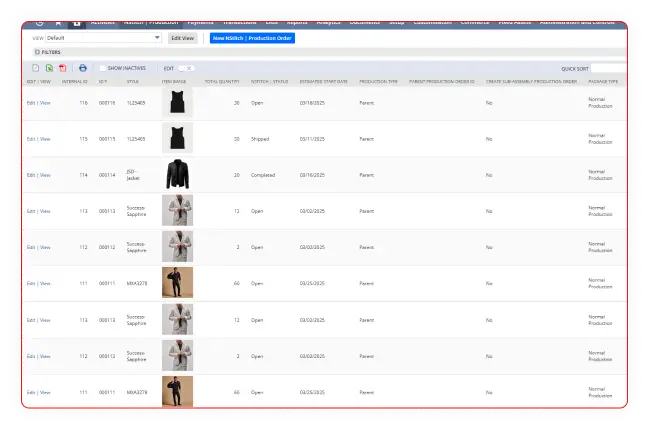

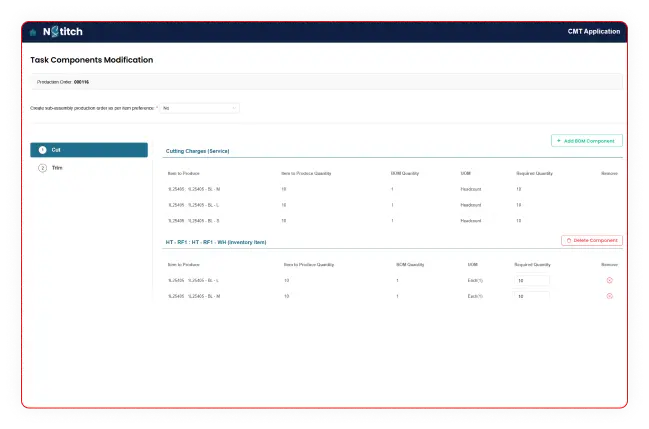

Track various stages of In-house and outsourced production processes with our Cut-Make-Trim NStitch solution.

Gain a complete view of customer interactions across all business channels while tracking sales and marketing performance.

Drive sales and provide a delightful shopping experience by enabling your sales reps to gain a 360 view of your customers.

Grow your business by maximizing your web presence using a single robust eCommerce platform.

Service both B2C and B2B customers with ease by managing operations using a single unified platform.

Generate purchase orders for outsourced services and seamlessly integrate them into your cost structure.

Accurately track labor, overhead, and material costs to provide a complete view of production expenses.

Monitor linked production orders across all stages, reducing manual work and ensuring every step is tracked

Stay on top of your inventory with real-time tracking of materials as they’re used in production.

Track full-package outsourced production processes and manage all external vendors from one platform.

Easily manage rework or repair tasks for returned goods, ensuring they’re ready for resale.

Cancel production orders at any stage, transfer unused materials back to your warehouse, and record incurred costs accurately.

Generate detailed reports like CUT tickets for production clarity, cost analysis reports for process improvement, and task tracking to monitor production timelines.

Automatically create transfer orders to move raw materials from warehouses to production or vendor locations, ensuring timely delivery to prevent production delays.

Manage lot-numbered items for both components and finished goods with ease.

Track and manage repairs for returned goods, allowing you to get products back on the sales floor faster.

Ideal for businesses looking to grow, optimize their production, and reduce costs.

Perfect for larger businesses that need full visibility and control over every aspect of their operations.

Manage and track production across multiple vendors and locations with ease.

Folio3 implemented NetSuite ERP for Naked Wardrobe to consolidate its disparate systems (Magento, ShipStation, Excel spreadsheets). The implementation involved significant customizations to manage orders at the style level crucial to the fashion industry. Customizations, like the collection-based PO creation, addressed specific business needs and significantly reduced manual work.

It streamlines workflows, reducing manual paperwork, enabling better inventory control, managing seasonal demand fluctuations, and providing real-time insights for timely decision-making.

© 2025, Folio3 Software Inc. All rights reserved.